Pipe Relining Limitations: When We Say ‘Don’t Do It

Understanding pipe relining limitations is crucial for Sydney homeowners deciding between trenchless repair and full pipe replacement for blocked drains or broken pipes. Pipe relining is a revolutionary repair method, but it isn’t a magic bullet. An honest company will tell you when it’s the wrong choice. While relining often saves time, money, and disruption compared to excavation, there are real situations where it simply won’t work — and knowing these limits can save you from costly mistakes.

So, when should you trust an expert who tells you, “Pipe relining won’t work for your home”? This comprehensive guide uncovers the real pipe relining limitations and explains the scenarios when we say no.

For a full overview of trenchless repair and alternatives, see our complete guide to Pipe Relining Sydney

Pipe Relining Limitations: Is Trenchless Pipe Repair Always the Best Solution for Blocked Drains?

Is pipe relining always a better choice than excavation? Not necessarily. While pipe relining can save property owners significant time and prevent landscape destruction compared to traditional pipe replacement methods, it’s not suitable for every damaged pipe or plumbing system. Understanding these boundaries ensures you don’t waste money—or end up repairing the same problem twice.

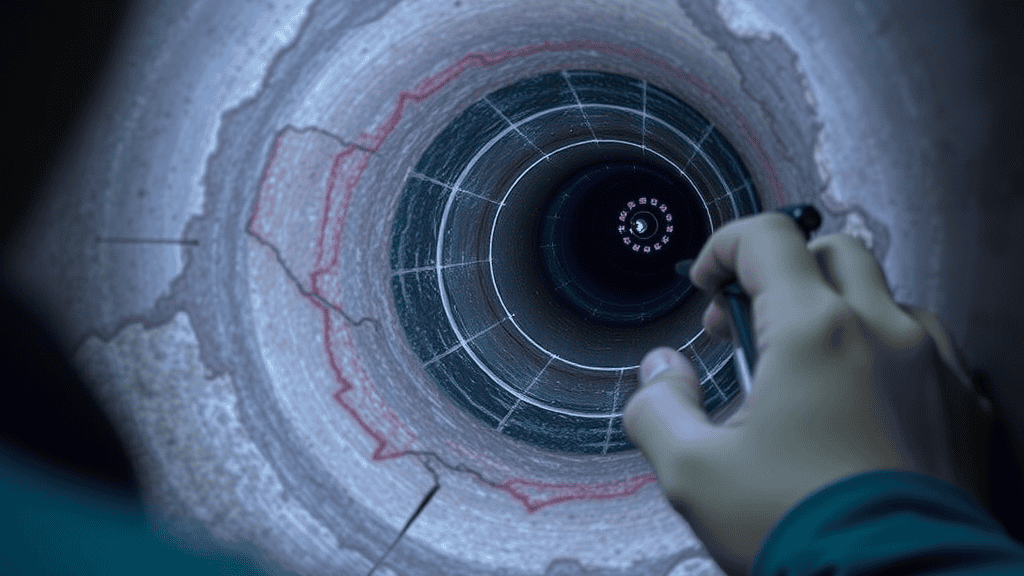

From severely collapsed sewer pipes, sections completely missing, to pipes suffering from a severe backfall or “belly” (incorrect slope), various issues put traditional methods back in the spotlight. Every reputable plumber will assess the specific condition of your plumbing system using drain cameras and other tools before recommending any pipe repair option. Identifying the true state of your pipes lets you make an informed decision between pipe relining and full pipe replacement.

Let’s dive into when and why relining isn’t appropriate—saving you from poor investments and persistent headaches.

What You’ll Learn About Pipe Relining Limitations

A clear understanding of pipe relining limitations

Scenarios where trenchless pipe repair is not suitable

Differences between pipe relining and pipe replacement

How a trusted plumber assesses whether pipe relining is feasible

Answers to common questions about pipe relining disadvantages

Understanding Pipe Relining and Its Advantages

Pipe relining, sometimes called cured-in-place pipe lining, is a trenchless technology that enables professionals to repair damaged pipes from the inside. The relining process involves inserting a resin-soaked, flexible liner into the existing pipe and inflating it until it forms a tight, cured “pipe within a pipe.”

This method appeals to property owners because it avoids major excavation, reduces site damage, and restores flow in a fraction of the time required for traditional pipe replacement.

Trenchless pipe repair reduces excavation and site damage

The relining process is often faster than pipe replacement

Advantages of pipe relining for sewer pipes and drains

"Pipe relining can save property owners time and money—but only when it's actually appropriate for the situation."

For many homes with blocked drains, root intrusion, or minor corrosion, pipe relining offers a life-extending pipe repair solution. It restores the plumbing system with minimal disruption and is suitable for cast iron, clay, and other common pipe materials—provided the pipe still has enough integrity for the liner to adhere. But even as technology improves, not all damaged pipes are candidates for this convenient solution.

If you’re dealing with persistent blockages or suspect your pipes are cracked, it’s important to understand the specific repair options available. For a closer look at how pipe relining addresses cracked pipes and when it’s most effective, explore our detailed guide on relining cracked pipes versus replacement.

Key Pipe Relining Limitations: When We Advise Against It

While the advantages of pipe relining are significant, its limitations matter just as much—sometimes more. The most honest and reputable plumbers will tell you point blank when trenchless pipe repair won’t work. Here are the key scenarios when we tell customers, “Pipe relining isn’t an option for you.”

Collapsed Pipe: Why You Can’t Reline a Pipe That Has Fully Failed

Imagine trying to put a stent in a completely crushed artery—it simply won’t work. Similarly, if an existing pipe has fully collapsed and lost its structural shape, pipe relining is off the table. The liner used in the trenchless process needs a host pipe to “mold” against as it cures. In the case of a broken pipe with full collapse, there is nothing for the liner to cling to, resulting in an unsuccessful repair. Excavation and traditional pipe replacement are the only options when a pipe is crushed, shattered, or missing large chunks of its circumference.

"A liner needs a pipe to mold against—if it’s crushed, relining is impossible."

Typical signs of a fully collapsed pipe include sudden or repeated blockages, water backing up into the property, persistent sinkholes, or the discovery of voids during drain camera inspection. When the pipe has completely failed structurally, even the most advanced lining techniques can’t restore flow or prevent leaks. The only viable remedy is to excavate and install new plumbing, ensuring your plumbing system is safe from ongoing damage.

Severe Backfall or ‘Belly’: When the Slope is Wrong

If your sewer or stormwater pipe has a significant “belly”—a sagged section where the slope is reversed or water pools—pipe relining is likely the wrong approach. The relining process copies the existing slope of the pipe. So, while it may restore the pipe’s inner wall and prevent leaks, relining will not fix drainage issues caused by an incorrect slope.

"Relining copies the existing slope. If water already pools in your pipes, relining only preserves the problem."

Homeowners often hope that pipe relining will resolve blocked drains caused by persistent water sits or poor flow. However, unless the pipe is physically re-graded, the belly persists, and so do your drainage headaches. In these situations, excavation and reinstallation—resetting the pipe with the correct slope—is the correct (and sometimes sole) solution. Always trust an assessment by a professional plumber, who can use a drain camera to identify latent slope problems that relining alone cannot address.

Issue | Description | Solution |

|---|---|---|

Collapsed Pipe | Pipe has no structural integrity | Pipe replacement required |

Pipe with Belly | Incorrect slope causes pooling | Excavation and regrading necessary |

Missing Sections | Gaps prevent liner from adhering | Reconstruction of missing areas first |

Missing Pipe Sections: No ‘Mold,’ No Relining

Trenchless pipe repair depends on an existing pipe to act as a mold for the resin liner. If sections of your sewer pipe are completely missing—perhaps lost to aggressive tree root intrusion, corrosion, or previous improper repairs—there is nowhere for the liner to adhere. This results in an ineffective or even failed relining attempt.

In these cases, even the most skilled plumber cannot achieve a reliable fix with relining alone. The process involves inserting the liner through the intact areas, but where there’s only dirt or void, the liner can’t bond, cure, or support water flow. The smart solution? First reconstruct or patch missing segments using pipe replacement, then evaluate if the remaining portions are suitable for relining. This combined approach protects your plumbing system and maximises the life of the repair.

Understanding the Risks and Challenges of a Failed Relining Attempt

While this guide focuses on when pipe relining isn’t suitable, it’s also crucial for homeowners to understand the potential risks and challenges should an unsuitable pipe be incorrectly relined, or if the process simply fails. Attempting to reline a pipe with extensive corrosion, large missing sections, or a severe backfall can lead to a host of significant problems.

Firstly, an insufficient bond between the new liner and the host pipe can result in persistent leaks, allowing water and waste to escape into your property’s soil, potentially causing further structural damage or environmental contamination.

Secondly, if the liner doesn’t cure correctly or is compromised by existing obstructions, it can create new blockages within the pipe, leading to recurring drainage issues that are even more difficult to resolve due to the now double-walled pipe structure.

Finally, a failed relining can make future repair efforts considerably more complex and expensive. Excavation might still be required, but now plumbers must contend with both the original damaged pipe and the failed liner, which can be challenging to remove.

This highlights why a thorough, honest assessment of pipe relining limitations by a qualified professional is paramount; it protects you from poor investments and persistent headaches, ensuring the chosen solution is truly effective and long-lasting.

Pipe Replacement vs Pipe Relining: Making the Right Choice

It’s critical to determine the benefits and limitations of both pipe relining and traditional pipe replacement. Each method suits specific situations, and a professional plumber’s assessment will weigh all factors: structural integrity, pipe material, severity of damage, and property constraints.

Pipe Relining Suitability Checklist

Your pipe has minor to moderate damage (not fully collapsed or missing sections).

No significant “belly” or slump in the existing pipe.

The material (cast iron, clay, most plastics) is compatible with lining process.

Internal diameter and length fall within relining system tolerances.

Accessible entry points exist for the relining equipment.

Signs Your Sewer Pipe May Need Replacement

Pipe is fully collapsed or caved in.

Large gaps or entire pipe sections missing.

Extreme corrosion or fragmentation (often in older cast iron pipes).

Persistent drainage issues related to pipe slope (“belly”).

Extensive tree root intrusion through large voids.

Steps Involved in the Assessment Process

Professional plumber inspects pipes using a drain camera.

Documents are made of all sections: intact, damaged, and problematic.

Assessment considers surrounding soil, potential excavation risks, and property layout.

Customer receives clear explanation of the pros and cons for each solution.

Final decision made based on safety, cost, and long-term outcomes.

Choosing between pipe relining and pipe replacement for your plumbing system is not always straightforward and requires a professional plumber’s thorough assessment. Reputable plumbers give honest, evidence-based recommendations—never pushing relining as a cure-all if traditional methods offer a longer-lasting solution. Sometimes, blending both methods—repairing the worst areas by replacement, then relining the rest—delivers the strongest result for your plumbing system.

For a closer look at how pipe relining addresses cracked pipes and when it’s most effective, explore our detailed guide on relining cracked pipes versus replacement.

The Cost and Long-Term Value of Pipe Relining vs Replacement

When weighing pipe relining limitations, cost is often the deciding factor for Sydney homeowners. On average, pipe relining costs less upfront than full excavation and replacement, especially when landscaping, driveways, or tiling would otherwise need to be dug up and restored. Relining minimises disruption, meaning you’re not paying to rebuild gardens, paths, or structures after the job.

However, the true value lies in long-term performance. A properly relined pipe can last 50 years, delivering a lifespan comparable to new piping. That said, relining only works if the existing pipe meets the suitability checklist. Relining a pipe with major defects—like a severe belly or collapsed section—may lead to repeat failures and more costs down the track. In these cases, paying more for replacement upfront saves you from compounding expenses later.

For many properties, a hybrid approach offers the best return: replacing the most compromised sections while relining the rest. This strategy balances immediate affordability with long-term reliability, ensuring your plumbing system is both structurally sound and cost-effective. Always request a clear, itemised quote that compares both options so you can make a financially informed decision.

Pipe Relining Limitations: Common Process and Material Considerations

Even with perfect conditions, pipe relining limitations exist based on process and materials. Not all pipes—especially those made from rare or highly deteriorated substances—are good candidates for the relining process. Additionally, obstructions such as heavy corrosion, scale build-up, and tree roots inside a pipe can prevent successful liner installation.

Limitations in the relining process for certain pipe materials

The impact of obstructions, heavy corrosion, and root intrusion

Length and diameter constraints for pipe relining

Diameter and length also matter. Most lining systems are designed for pipes within a certain size range; extremely narrow or extra-large pipes may not qualify. Root intrusion—if not cleaned and treated—can also undermine the relining process, allowing further pipe damage after relining.In cases of significant corrosion, especially in old cast iron pipes, relining might simply delay the need for inevitable full replacement.

Always expect your plumber to be transparent about pipe relining limitations—and avoid contractors promising quick fixes without a thorough, camera-assisted inspection. The best repair option is the one that delivers safety, reliability, and genuine value for your plumbing system in the long term.

People Also Ask About Pipe Relining Limitations

What are the limitations of pipe relining?

Pipe relining has several key limitations. It cannot restore pipes that are structurally unstable, such as those that are fully collapsed or have significant sections missing. Relining is also ineffective if the sewer pipe has a severe “belly” or downward slope issue, as the liner will simply replicate the faulty alignment.

Other challenges include inaccessibility due to pipe material (extreme corrosion or incompatible plastics), the presence of persistent obstructions (such as scale or root intrusion that cannot be fully cleared), and pipes that are outside the diameter or length range for the lining process. In all such cases, traditional pipe repair or replacement is a better long-term solution.

What are the disadvantages of relining?

While pipe relining can restore functionality to many moderately damaged pipes, it comes with certain drawbacks. The process is less effective if there are severe blockages or deformities, as the liner won’t fully bond or may even fail. Relining does not fix sloping or “belly” problems—these must be addressed through proper regrading.

Furthermore, while relining offers minimal disruption, it’s sometimes no more cost-efficient than careful excavation, especially if preparatory work is needed for collapsed or missing sections. Finally, in the rare event that relining fails, accessing the now double-walled pipe for further repairs can become more complicated.

What are the limitations of cured in place pipe lining?

Cured-in-place pipe lining, or CIPP, faces similar issues as standard pipe relining. It cannot be used on pipes that are too deteriorated, collapsed, or have large gaps. The curing process requires intact host pipes for optimal results, and any presence of heavy debris, corrosion, or severe root intrusion can result in liner failure.

The effectiveness of CIPP also relies on proper cleaning and preparation—a neglected step can lead to leaks or separation down the line. Moreover, CIPP liners vary in temperature and pressure tolerances by manufacturer, so older or highly unique plumbing systems may not be compatible.

How effective is pipe relining?

When applied in the right scenarios, pipe relining is highly effective for extending the life of sewer pipes and drains. The new liner seals leaks, prevents further root intrusion, and restores flow with minimal disruption. Most relined pipes last 20-50 years under normal use, nearly matching the performance of fully replaced pipes.

However, the process is only as good as the condition of the existing pipe and the expertise of the installer. If fundamental problems—such as collapse, slope issues, or missing pieces—exist, pipe relining cannot deliver a safe or lasting fix. Always work with a reputable, experienced plumber to maximize the effectiveness of any relining project.

Additional FAQs About Pipe Relining Limitations

Can pipe relining fix all types of damaged pipes?

No. Pipe relining works for pipes with moderate to mild damage, but not for those that are fully collapsed, missing significant sections, or have extreme deformation. Structural stability is essential for the success of the relining process.

Is pipe relining more cost-effective than pipe replacement in every case?

Not always. While it reduces excavation and saves time, situations needing extensive prep work or involving severe blockages may make traditional replacement more economical in the long run. Each case requires a detailed cost-benefit analysis.

What is the typical lifespan of a relined pipe?

A professionally installed relined pipe can last 20-50 years, depending on usage, pipe material, and environmental factors. Lifespan is maximized with proper cleaning and skilled installation.

Are there minimal disruption benefits if extensive excavation is needed anyway?

Minimal disruption is the main advantage of trenchless pipe repair. But if pipe sections must be physically replaced or excavated due to collapse or severe slope, that benefit is significantly reduced.

Key Takeaways: Pipe Relining Limitations You Should Know

Pipe relining can’t fix collapsed, heavily sloped, or missing pipe sections

A thorough inspection determines your best repair option

Reputable plumbers will advise when relining isn’t appropriate

When Pipe Relining Might Not Be the Best Choice

Not every pipe can be saved with relining. Here are the key situations where we advise against it — and why a different repair option is smarter.

Severely Damaged or Collapsed Pipes

If a pipe has completely collapsed, is heavily compromised, or has large sections missing, relining isn’t possible. The liner needs a stable, existing structure to bond to. In these severe cases, excavation and replacement are usually the only way to restore full integrity.

Significant Pipe Misalignment or “Bellies”

When pipes sag or slope incorrectly, water pools inside them. Relining simply copies that slope — so the problem sticks around. To fix drainage issues caused by a belly, the pipe needs to be dug up and reset at the proper grade.

Extensive Corrosion or Material Incompatibility

Old metal pipes that are badly corroded, or pipes made from incompatible materials, often can’t hold a liner properly. If the bond fails, you end up with wasted money and another repair bill. In these cases, replacement is often the more reliable choice.

Reduced Internal Diameter

Adding a liner inside a pipe reduces its diameter slightly. Usually it’s not a problem, but if your drains are already running near full capacity, that extra layer can affect flow.

Risk of Improper Installation

Relining only works if the pipe is thoroughly cleaned, the liner is cured correctly, and the installer knows what they’re doing. If any of these steps are skipped, the result can be leaks, blockages, or complete failure. That’s why choosing an experienced, reputable plumber is non-negotiable.

Conclusion: Trust Experts to Diagnose Pipe Relining Limitations

Pipe relining can be a brilliant solution, but it’s not a one-size-fits-all fix. The best plumbers will tell you straight when relining isn’t the right option — and guide you toward the safest, most cost-effective long-term repair.

When you work with an honest professional, you won’t be left guessing. They’ll use a drain camera to show you exactly what’s going on underground and explain whether relining, replacement, or a mix of both will give you the strongest result. That way, you can make decisions confidently, knowing you’re not throwing money at a quick fix that won’t last.

If you’re unsure whether relining is right for your drains, don’t leave it to chance. Book a diagnostic inspection today and get expert advice tailored to your home. A proper assessment now can save you thousands later — and give you peace of mind that your plumbing is truly protected for the long run.